PROJECT OWNER

William & Mary College

PROJECT NAME

North Campus Power Plant – Boiler Renovations

LOCATION

Williamsburg, VA

ROLE

Prime Contractor for All Construction

PROJECT YEARS

2008-2009

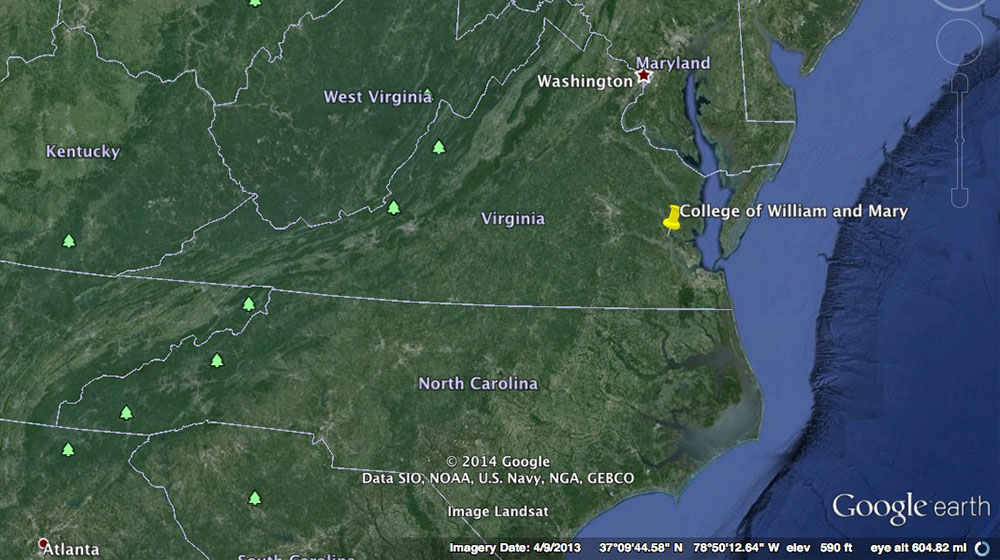

College Of William and Mary

The College of William and Mary (W&M) campus is located on 1,200 acres in Williamsburg, VA and includes 93 buildings serving academic, administrative, athletic, laboratory, and student housing functions. Due to planned campus growth and aging utility infrastructure systems, a utility master plan was commissioned to optimize the campus utility upgrades.

The Central Heating Plant was 50 years old, and a comprehensive condition assessment was performed to establish the extent of the modernization of the system. The boilers, auxiliaries, piping and building structure were surveyed and evaluated to determine the remaining useful life of the individual components. RMF engineers prepared the construction plans, specifications, and calculations related to the design. Frank Lill and Son, Inc. was the prime contractor responsible for all construction.

The heating plant upgrade consisted of the removal of existing Boiler Nos. 1, 3, and 4, and the installation of three new gas/oil fired boilers. This new system provides the needed operational flexibility during peak and summer load conditions as well as reduces fuel consumption through increased boiler efficiency.

Temporary valves were installed in the high pressure steam distribution and condensate piping during a routine outage. These valves were installed to permit the planned plant renovations of Phase 1 to occur while a temporary steam plant provided steam through these new fittings to the distribution system. Additional features and new components of the heating plant renovation included:

- Temporary boiler and auxiliaries

- Deaerator

- Water softening system

- Underground No. 2 fuel oil tank

- Feedwater and condensate pumping systems

- HVAC systems throughout the plant

- Compressed air, atomizing air, and instrument air systems

- Blowdown and continuous blow off systems

- Electrical service upgrades

- Emergency generator serving all boiler loads

- Main entrance access ramp

- Mezzanine level and catwalk system

- Modern control system

- Electrical switchgear room